Toilet Flange Repair - Troubleshooting and Fixing Common Issues

Toilet Flange Repair - Troubleshooting and Fixing Common Issues

Blog Article

What're your beliefs about Toilet Flange Repair?

Intro:

Recognizing the Importance of a Toilet Flange:

In the world of plumbing, the often-overlooked bathroom flange plays a crucial duty in making certain the smooth procedure of your bathroom components. As a vital connector between your toilet and the underlying drain, the toilet flange serves as the unhonored hero of your plumbing system. Without this strong component, your commode would be prone to instability and leaks, possibly leading to expensive repairs and inconvenience. As a result, understanding the significance of a correctly installed and kept toilet flange is extremely important for any type of property owner starting plumbing projects or dealing with repair work needs.

Why Proper Installation and Maintenance Matter:

Correct installation and meticulous maintenance of the toilet flange are vital for securing the stability of your plumbing framework. A thoroughly installed flange not just anchors your bathroom securely in position but additionally develops an impenetrable seal, fending off the perils of leaks and smells. By embracing a positive strategy to flange maintenance, you can mitigate the risk of disruptive plumbing concerns and maintain the tranquillity of your home atmosphere. Throughout this informative guide, we'll decipher the ins and outs of commode flange installment and fixing, empowering you with the knowledge and competence to browse these essential jobs expertly.

Ideal Practices When Installing a Toilet Flange:

Making certain a smooth bathroom flange setup requires adherence to a collection of ideal techniques that guarantee resilience and functionality. Begin by meticulously evaluating your devices and materials, guaranteeing you have the essential equipment for the task in advance. Selecting the proper flange product, whether PVC, ABS, or cast iron, is paramount, as it identifies the long life and performance of your plumbing component. Moreover, evaluating existing plumbing problems, such as checking for damages or deterioration, is necessary for preemptively resolving prospective complications and making certain a smooth setup process. By adopting these preparatory actions, you set a solid foundation for an effective toilet flange setup, minimising the probability of future problems and facilitating long-term maintenance.

When effectively ready, proceed with the cautious removal of the old flange, following a systematic technique to avoid creating damages to bordering parts. Use strategies tailored to deal with stubborn or rusted flanges, ensuring their swift and risk-free elimination without endangering the honesty of the surrounding plumbing infrastructure. With the old flange removed, thoroughly set up the new substitute flange, selecting one that fits well and firmly into location. Correctly safeguarding the flange to the floor utilizing screws or adhesive is important, as it makes sure security and stops future leakages. By sticking to these ideal practices during the setup procedure, you prepared for a durable and dependable toilet flange configuration that holds up against the examination of time.

Mounting a New Toilet Flange:

When setting up a new bathroom flange, the first step is to select the appropriate replacement for your plumbing configuration. Take into consideration elements such as the product of the flange, with choices including PVC, ABS, or cast iron. PVC flanges are understood for their affordability and resistance to corrosion, making them a prominent choice for DIY enthusiasts. Abdominal muscle flanges provide similar benefits to PVC however brag added sturdiness, making them suitable for high-traffic areas or commercial setups. Cast iron flanges, renowned for their toughness and durability, are suitable for setups where toughness is extremely important. In addition, make certain that the substitute flange is correctly sized and fits snugly right into location to create a water tight seal and avoid leakages.

Protecting the Flange to the Floor:

As soon as you've chosen the ideal replacement flange, it's crucial to safeguard it appropriately to the flooring to make certain stability and protect against future problems. Begin by placing and lining up the flange appropriately over the waste pipe, making certain that it sits flush with the flooring surface area. Depending upon the kind of flange and your particular installment preferences, you can safeguard the flange to the flooring making use of screws or adhesive. If making use of screws, make sure to make use of corrosion-resistant alternatives to stop rusting gradually. Additionally, adhesive can provide a safe and secure bond in between the flange and the flooring, making certain a strong and trusted installation. By following these steps and taking the essential preventative measures, you can set up a new toilet flange with self-confidence, ensuring a durable and leak-free plumbing fixture.

Ideal Practices When Repairing a Broken Flange:

Repairing a broken commode flange demands thorough attention to information and adherence to finest methods to make certain a lasting service. Begin by thoroughly evaluating the degree of the damages and identifying the underlying reason, whether it be deterioration, splits, or misalignment. This assessment will direct your repair technique, enabling you to select one of the most suitable strategies and materials for restoring the flange to its optimum problem. Additionally, consider the surrounding plumbing framework and flooring security to attend to any type of potential adding aspects and prevent future issues from arising. By carrying out an extensive analysis and analysis, you lay the groundwork for a reliable and enduring repair process that resolves the root cause of the issue.

With a clear understanding of the flange's problem and the variables influencing its damages, wage the fixing procedure making use of accuracy and care. Depending on the severity of the damages, you may opt for fixing techniques such as epoxy putty, repair service flange sets, or partial flange substitutes. Make sure that the chosen fixing technique efficiently deals with the particular issues at hand while preserving the architectural stability and functionality of the flange. Furthermore, take aggressive actions to strengthen the repaired flange and avoid future damages, such as applying sealant or waterproofing materials to secure versus leaks and rust. By adhering to these best practices during the repair service procedure, you can recover your busted flange to optimum condition, guaranteeing the long-term integrity and performance of your plumbing system.

Kinds Of Toilet Flanges:

Comprehending the different kinds of toilet flanges is crucial for choosing the most appropriate alternative for your plumbing needs. PVC, ABS, and cast iron are amongst the usual materials made use of in commode flange building and construction, each offering distinct benefits and factors to consider. PVC flanges, known for their cost and corrosion resistance, are favoured for their convenience of installation and durability. Abdominal muscle flanges, similar to PVC in terms of affordability and ease of setup, are treasured for their robustness and resistance to effects. On the other hand, cast iron flanges, renowned for their exceptional toughness and longevity, are often chosen for high-traffic areas or commercial setups where resilience is paramount. By familiarising on your own with the qualities of each product, you can make a notified decision when choosing a commode flange that aligns with your specific needs and choices.

Along with material factors to consider, commode flanges additionally can be found in different design and styles to accommodate various plumbing arrangements and setup preferences. Offset flanges, as an example, are developed to suit toilets mounted on floors that are uneven or where the waste pipe lies off-centre. Similarly, repair service flanges, additionally known as repair service rings or spacer rings, are made use of to address problems such as cracked or broken flanges without the requirement for considerable plumbing modifications. Furthermore, adjustable flanges use adaptability ready, permitting precise positioning and fit during installation. By checking out the diverse variety of bathroom flange types and styles readily available, you can pick the alternative that ideal fits your plumbing configuration and setup needs, guaranteeing a smooth and trusted service for your bathroom fixtures.

Specialty Options:

Along with conventional commode flanges, there are specialty choices available to address particular plumbing obstacles and installation preferences. One such alternative is the offset flange, which is created to suit bathrooms mounted on floors that are not level or where the drain is located off-centre. Offset flanges feature a special layout that permits the commode to be positioned at a minor angle, making up for irregular flooring or misaligned plumbing connections. This innovative solution guarantees a protected and stable installation, eliminating the need for pricey and time-consuming flooring progressing or pipeline moving. By integrating an offset flange into your plumbing arrangement, you can get rid of typical installation obstacles and attain a professional-quality outcome easily.

An additional specialized alternative worth taking into consideration is the repair work flange, also referred to as a repair work ring or spacer ring. Repair flanges are especially designed to address issues such as cracked or damaged toilet flanges without the requirement for comprehensive plumbing alterations. These flexible parts can be set up straight over the existing flange, supplying a sturdy and dependable base for securing the toilet in place. Repair flanges can be found in various dimensions and arrangements to suit different flange diameters and setup needs, making them a convenient and affordable remedy for solving flange-related problems. Whether you're handling a minor flange repair work or a much more intricate plumbing problem, incorporating specialty options like countered and repair service flanges can enhance the installation process and ensure lasting performance for your bathroom components.

Final thought:

In conclusion, understanding the art of toilet flange setup and repair is vital for maintaining a useful and leak-free plumbing system in your home. By recognizing the importance of an effectively set up flange and sticking to best methods throughout the procedure, you can guarantee the durability and integrity of your restroom components. Whether you're picking the appropriate type of flange, carrying out repair work, or checking out specialized alternatives, focus to information and precise execution are vital. Regular upkeep and aggressive troubleshooting can aid avoid costly plumbing issues and preserve the peace of your household setting. Equipped with the understanding and skills gained from this extensive guide, you can deal with toilet flange installment and repair work with self-confidence, equipping you to safeguard your plumbing system for years ahead.

How to Replace a Toilet Flange That’s Old or Broken

Turn Off the Water Supply

As with many other plumbing tasks, the first step is to turn off the water supply to the toilet so you don’t end up dealing with a messy leak. Look for the shut-off valve on the wall behind the toilet—typically located closer to the floor—and turn it all the way clockwise.

Empty the Toilet Bowl and Tank

Now, it’s time to drain the water remaining in the bowl and tank and confirm that the supply line is fully closed. Flush the toilet a few times until the bowl no longer fills with water. You can use a plunger to drain any small volume of water lingering at the bottom of the basin. If the tank continues to replenish the bowl after a few tries, you need to go back to step one and keep turning the knob on the water supply until it’s all the way off.

Disconnect the Water Supply

Set down towels or a tarp on the bathroom floor to keep it safe from the moderate water runoff that can happen while disassembling a toilet. Look for a hose, usually made of braided metal, that runs from the tank to the joint with the shutoff valve.

Loosen it at the end attached to the fill valve on the underside of the toilet. If you have trouble doing so by hand, try using an adjustable wrench. Expect a bit of water leakage when the hose disconnects.

Remove the Toilet Tank

Look for the two or three mounting bolts on the bottom of the tank that connect it to the bowl on each side. Using your wrench, loosen the nuts from the bolts and set them somewhere safe and accessible. Carefully lift the tank up and off the bowl and set it aside. Take some time to review the parts of a toilet as you get ready for the next step.

Remove the Toilet Bowl

Now comes the hardest part. Be prepared to lift the toilet bowl—typically weighing between 70 and 120 pounds—off the ground. If you’re not confident you can safely lift and remove a toilet, you’ll need a helper on hand to help shoulder the weight.

The first step is to remove the caps from the bolts that secure the toilet's base to the floor. In most cases, there will be two of them on each side of the bowl. Use a screwdriver to pry off the caps, and then use the wrench to loosen and remove the nuts from the bolts. Set them aside for later.

Once you have removed the nuts, grab each side of the commode and gently rock it back and forth until it’s loose and the seal of the wax ring beneath the base breaks.

The bowl is now ready to lift. Straddle the toilet and crouch, reaching down until you have a grip on the underside of the bowl. Stand steadily and slowly, lifting with your legs, until the bowl is off the bolts. Set it down on its side on top of your tarp.

Unscrew the Mounting Bolts

Most likely, you’ll find that the flange mounts to the floor with four screws. Insert your screwdriver and turn each screw counterclockwise until it’s loose enough to remove. If the hardware is in good shape, you can set the pieces aside to reuse with your new flange.

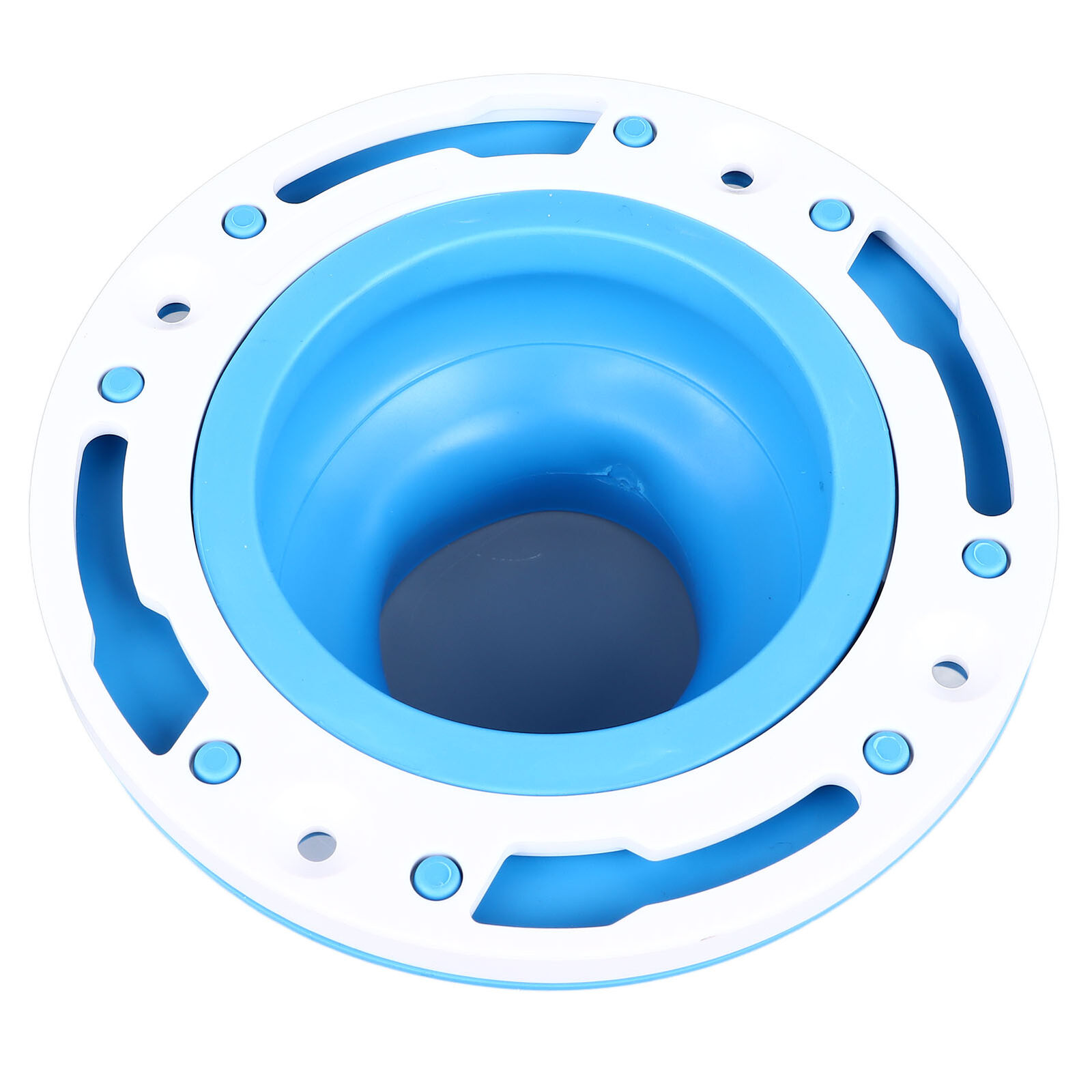

Lift the Flange to Remove

The flange is a circular fitting (2 to 3 inches in diameter) that sits underneath the toilet; it connects the internal drainage system to the drainpipe while securing the base of the toilet to the floor. Most toilets feature a PVC flange sealed with a gasket. If yours does, with the wax ring scraped away and the bolts loose, you can simply lift it up from the drainpipe and set it aside.

Toilet flanges do, however, come in various materials and can feature different fitting types. If you reach this stage and it turns out you have a metal flange glued in place or attached with a deep-seal fitting, you’ll need to stop and hire a plumber to take care of the rest of the job.

Otherwise, you can risk damaging the drainpipe—a significantly more expensive and complicated problem to address.

Before moving on to the next step, take the opportunity to examine the subfloor around your toilet. If any patches are soft or spongy, you should call a pro to quote the price to replace the damaged subflooring before proceeding further.

Measure the Outflow Pipe

Before installing a toilet flange, you’ll need to make sure you’ve got the right size. One option is to bring the old flange to the hardware store to find a match. Otherwise, you’ll want to take some measurements.

Before jumping into how to change a toilet flange, use the measuring tape to determine the diameter of the old flange, double-checking to confirm you’ve done it right. Make sure to buy a flange that matches the size, shape, and material of the old one—as well as a new wax ring if there isn’t one in your new flange kit.

Fit and Install the New Toilet Flange

Once you’ve got an appropriately-sized new flange, it’s time to start setting the new toilet flange. Remove and throw away the rags or towel from the outflow pipe.

Fit the new flange snugly into the outflow pipe, creating a seal with the gasket and resting the outer lip flush to the floor. Using the included hardware, secure the flange to the subfloor with screws and slide on the toilet flange bolts. Remember to tighten the washers or nuts fully.

Add the New Wax Ring

There are two different ways to install the new wax ring: Securing it either to the flange or to the toilet base. The latter is the preferred option among pros and the better choice if you have the space and muscle to do so. With the commode lying on its side on the floor or tilting it upward, attach the replacement wax ring directly to the hole at the bottom and ensure it’s fitted correctly.

If attaching it to the toilet seems too tricky, you can simply place the wax ring on the flange, centering it around the hole.

Replace the Toilet Completely

With the replacement flange in place, all you need to do is reassemble the toilet. Lift the toilet from the floor—making sure to engage your leg muscles to avoid straining your back—and place it on top of the new flange. Be sure to line up the holes at the base with the flange bolts. Once it’s resting evenly, apply steady downward pressure from the top of the bowl to seal the wax. Be careful not to rock or wobble it so that you don’t break the seal.

With the hardware you set aside, secure each of the bolts on the bowl with the nuts and washers—turn them tightly enough to prevent the toilet bowl from wobbling but be careful not to over-tighten them and risk cracking the porcelain. Then replace the bolt caps.

Next, lift the tank and place it back on the bowl, aligning the bolts with the holes. With the nuts you set aside, tighten the bolts until the bowl and tank are evenly and securely aligned. Reattach the supply hose to the toilet tank. Slowly turn the valve to gradually open it, testing for leaks as water begins to flow back into the toilet. Once the tank has filled, flush the toilet and keep an eye on the base, making sure there’s no leakage at the base of the toilet.

https://www.angi.com/articles/how-to-replace-toilet-flange.htm

As a serious person who reads about How to Replace a Toilet Flange, I figured sharing that portion was essential. Do you know about someone else who is interested by Toilet Flanges? Why not share it. Many thanks for your time invested reading it.

Additional Information Report this page